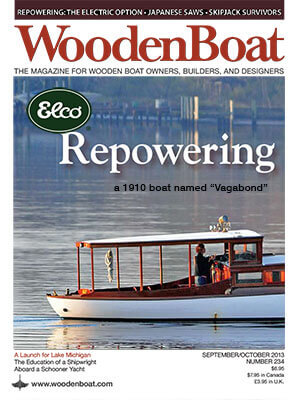

Late in 2010 David Gillespie approached Huckins Yacht Corporation, an authorized Elco Dealer from Jacksonville Florida for assistance with re-powering his treasured restoration project “Vagabond”, a 1910 Yacht built by Consolidated Shipbuilding. The story of the repower was featured in the October issue of Wooden Boat Magazine.